Heavy duty AC copper and aluminum radiator stripping separating recycling

1.Air Conditioner Copper Radiator Stripping Recycling Machine Introduce :

This radiator recycling machine is an environment-friendly equipment, used for separating copper pipes from aluminum. Designed and manufactured by us, This machine is a newly-designed compact one, taking up small area. Little materials (radiators) will be lost during processing, so this machine is practical and economical.

2.Copper And Aluminum Radiator Stripping Separating Recycling Machine Structure and Parameters:

- Machine Structure

This machine is consisted of a frame, two motors, two speed reducers, material feeding part, material cutting part, material separation part, transmission part and material feeding panel.

- Machine Parameters

Motor: 3kw (One Set) + 4kw (One Set)

Speed Reducer: 2 Sets

Voltage: 380v or Customized

Frequency: 50Hz/60Hz

Triangle belt: A Type (1200mm); B Type (1200mm)

Centerline of two copper pipes in radiators shall be 19mm or 21mm or 25mm.

our copper and aluminum radiator stripper recycling separator machine is suitable for all kinds of scrap radiator,single layer,double layer,3layer and 4layer waste radiator.

3: AC Radiator Copper and Aluminum Peeling Separating Recycling Machine:

G.W./N.W.:650/600KG PACKING SIZE:1.8*0.95*1.3 OUTPUT:3T(8HOURS)

|

Item

Model No. |

control |

protect |

Single and double radiator changing |

output |

Blades changing frenquency |

|

Radiator recycling machine(normal) |

Reversing switch |

Semi-closed |

By hands |

3t/day |

About 300T,only need to change less blades |

3.Notes before Working

Before delivery, the machine is already adjusted to the condition for processing radiators on the main market (19mm, 21mm, 25mm).

- Check if the power is connected well;

- Check if the Guiding Rulers for each part is at the right position;

- Check if the two Adjusting Wheels of each pair (total three) are on same level;

- Start the machine and check if the machine is running at the right direction.

4.Radiator Peeling Machine Material Preparation

Iron heads of radiators must be cut off the two sides of radiators;

Radiators must be cut with a band saw according to the width of each Material Inlet;

Radiators that are more than 2 layers must be cut into one layer and two layers with the band saw;

Do not feed radiators into wrong Material Inlets (three inlets each are for 19mm, 21mm, 25mm radiators respective);

This machine is suitable for processing one layer radiators when it is shipped to customers. When you need to process two-layer radiators, just remove the iron covers from the Lower Blade Roller to expose the blades.

When two-layer radiators are processed, the left side of the radiators shall touch the left side of each Material Inlet, and the first copper pipe in the Upper Layer to the left side of each Material Inlet must be nearer than the first copper pipe in the Lower Layer to the Left Side of each Material Inlet.

For both one-layer and two-layer radiators, the left side of radiators must touch the Guiding Rulers and are radiators must be fed into Material Inlets along the guiding rulers.

When radiators are fed into Material Inlets correct, each Feeding Gear at the Material Inlet must be at the middle of each two copper pipes; or copper pipes and aluminum will not be separated.

Twisted radiators can not be processed.

5.Scrap Air Conditioning Radiator Stripper Machine Processing:

Turn the Reversing Switch and check the rotating direction.

Inject oil into the two oil holes in the left and right side of the machine to lubricate transmission gears (normally once per 4 working hours).

Push different radiators into different Material Inlets according to their specs (19mm, 21mm, 25mm); the left side of radiators must touch the left side of Material Inlets; or, the right side of radiators must touch the right side of Material Inlets (the first copper pipe in the Lower Layer shall be nearer to the Guiding Ruler, different with Ⅳ.6); when radiators are pushed into Material Inlets, Feeding Gears will gnaw at radiators and take them into the machine.

After radiators are taken into the machine, copper pipes and aluminum are separated and come out of the machine automatically.

According to the layers of radiators and their height, adjust each pair of Adjusting Wheels on the machine (after adjusting, tighten screws below).

6.AC Radiator Stripping Recycling Machine Trouble-shooting

In radiator separating, if radiators move towards left direction or right direction, check if the two Adjusting Wheels of each pair are on the same level.

When abnormal noise appears in working, check the working conditions of transmission gears, bearings and Speed Reducer as well as motors.

When radiators can not be cut from top to bottom, check if Triangle Belts are loose which causes slipping; or check if the blades become blunt.

After working for a period, Speed Reducer lubricant shall be replaced; check if screws become loose or not; check if blades and Feeding Gears become loose or not.

- Buy Heavy duty AC copper and aluminum radiator stripping separating recycling for sale,price,Heavy duty AC copper and aluminum radiator stripping separating recycling exporter/importer,suppliers,factory,manufacturers in China.

-

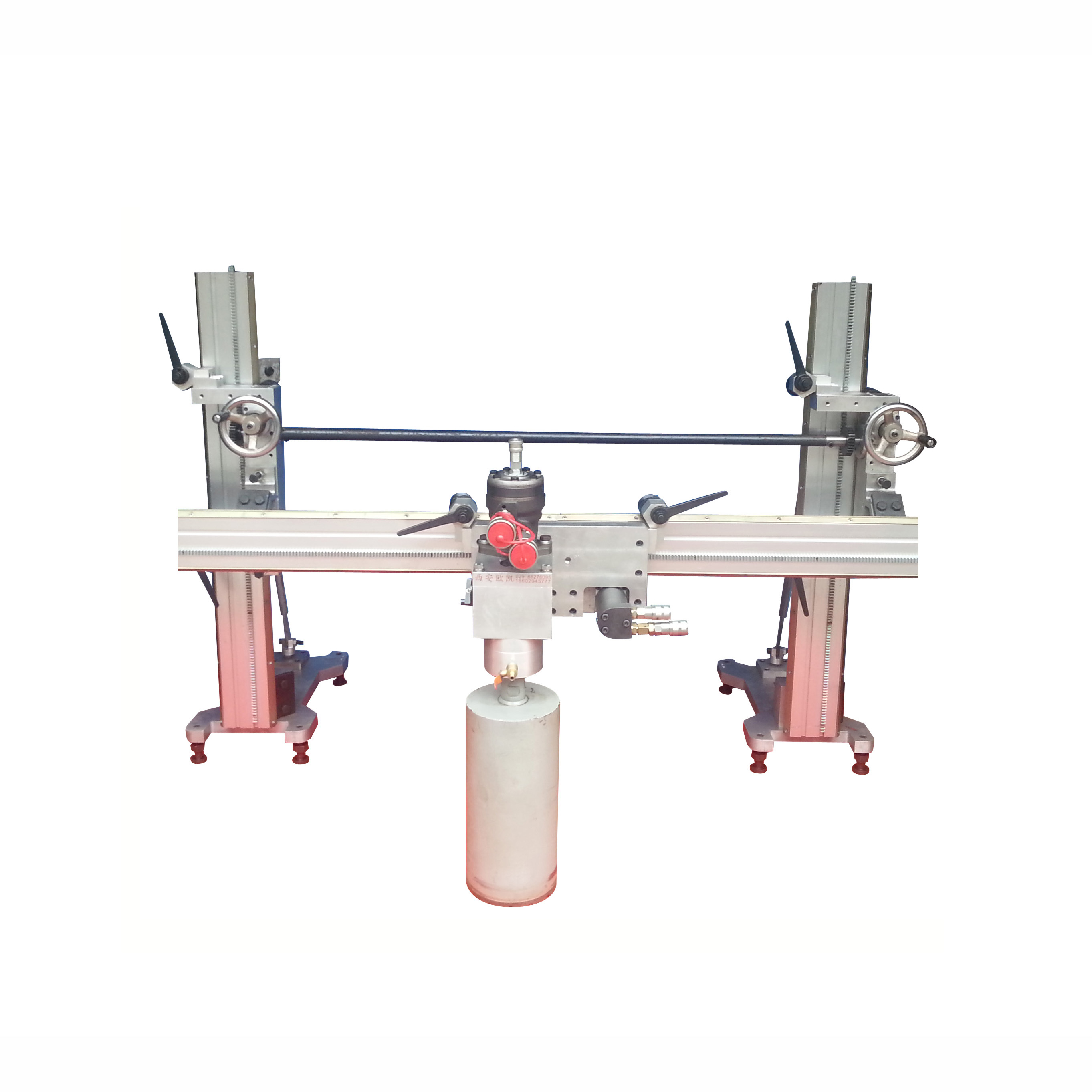

bs-20 мокрые канатной проволоки сепаратор машины

bs-20 мокрые канатной проволоки сепаратор машины

-

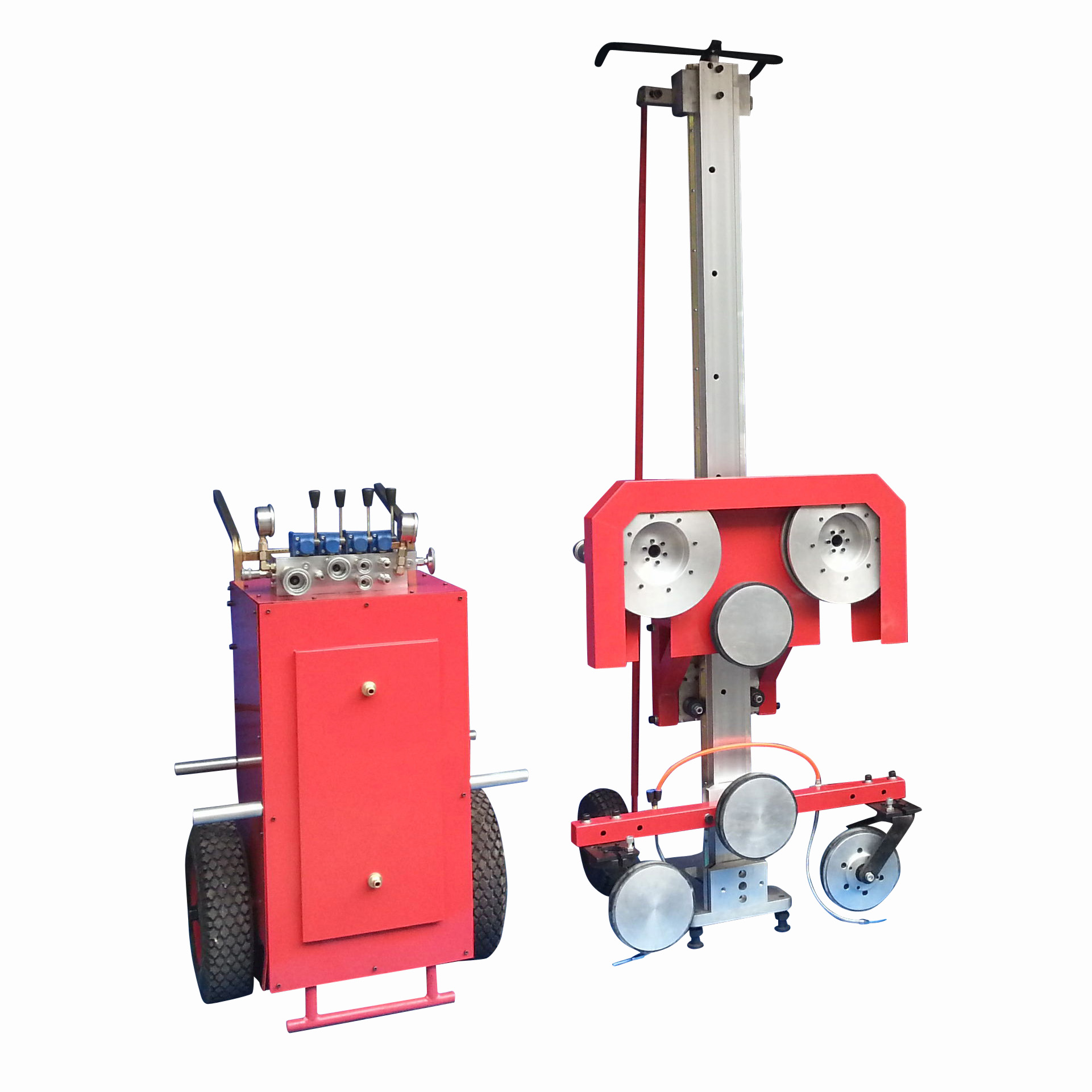

Alambre vio la máquina de corte de hormigón bs-90am Dimond

Alambre vio la máquina de corte de hormigón bs-90am Dimond

-

La máquina bs-hd90a hydrualic hormigón piedra populares herramientas de construcción

La máquina bs-hd90a hydrualic hormigón piedra populares herramientas de construcción

-

automatische verwendet, elektrischen draht - maschine (bs-013)

automatische verwendet, elektrischen draht - maschine (bs-013)

-

couper le béton de forages au diamant machine hydraulique

couper le béton de forages au diamant machine hydraulique

-

Cc-50b cortador de cabo

Cc-50b cortador de cabo

-

bs-009 الكهربائية مقشرة آلة سلك النحاس

bs-009 الكهربائية مقشرة آلة سلك النحاس

-

bs-300 سلك تجريد آلة

bs-300 سلك تجريد آلة

-

BS-300 strippen.

BS-300 strippen.

-

BS-1200P full protection waste air conditioner radiator stripper granulator machine

BS-1200P full protection waste air conditioner radiator stripper granulator machine

-

Newest Radiator Recycling Machine With Five Processing Sizes From BSGH Manufacturer Wholesale

Newest Radiator Recycling Machine With Five Processing Sizes From BSGH Manufacturer Wholesale

-

Multifunction Radiator Separating Machine From BSGH Equipment On Sale

Multifunction Radiator Separating Machine From BSGH Equipment On Sale

-

Most Technologically Advanced AC Coil Cutting Machine Radiator Stripping Recycling Production Line For Scrap Copper And Aluminum Separating Recovery

Most Technologically Advanced AC Coil Cutting Machine Radiator Stripping Recycling Production Line For Scrap Copper And Aluminum Separating Recovery

Wang Na

Wang Na